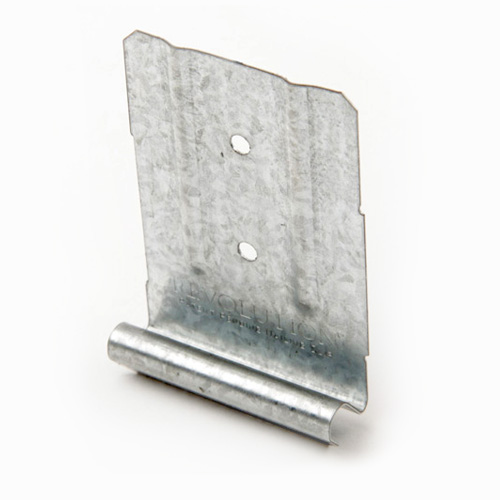

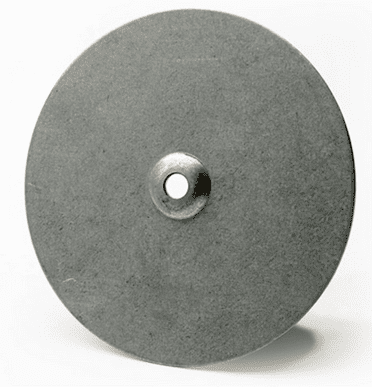

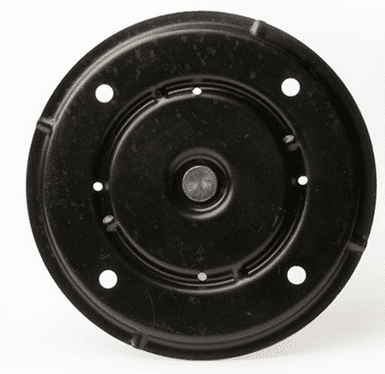

Metal Stamping

View Full Metal Stamping Parts Gallery >>

Talan Products’ high-speed metal stamping equipment and expertise are optimized for high-volume production meeting ISO 9001 quality standards. Our customers’ higher volume progressive die stamped parts may require production rates of up to 50,000 parts per hour, or more! Talan’s specialty focus on progressive metal stampings utilizes a combination of high-speed presses and progressive dies to provide the most cost effective solution for high volume manufacturing. We design & build specialized manufacturing cells utilizing automation when appropriate.

Metal Stamping Specialty Equipment & Expertise

At Talan Products, we take pride in our extensive lineup of metal stamping equipment and the deep expertise of our team. With over two dozen press lines, we have the right punch press for your part, ensuring optimal efficiency, precision, and cost-effectiveness.

State-of-the-Art Stamping Equipment

Our diverse range of presses includes a variety of:

- Tonnages to accommodate different material thicknesses and part complexities.

- Stroke lengths suited for intricate geometries and forming applications.

- Bed sizes that match the unique demands of each project.

Unlike other manufacturers who force parts to fit their equipment, we match the right press to your part, ensuring high-quality results and reduced production costs.

Expertise That Drives Performance

Our skilled professionals—from die makers to shop floor personnel and support staff—bring decades of experience to every project. Our team’s craftsmanship and technical knowledge ensure precision stamping, tool longevity, and efficient production runs.

Professional Material Management

Material procurement is critical to cost and performance. Our dedicated material management team stays ahead of industry trends, closely monitoring metals markets and publications to optimize sourcing and cost efficiencies for our customers.

Your Parts, Our Precision

We’re not just a stamping provider; we’re your manufacturing partner. Whether your project requires high-volume production, complex geometries, or tight tolerances, we have the right assets and expertise to deliver superior results.

Metals That Talan Excels at Stamping

We can work with all stainless steel alloys. We’re experts at stamping all popular aluminum alloys. We also frequently work with aluminum, copper, brass, Inconel, HSLA, galvanized, galvalume and carbon steels. We will be happy to assist in choosing the right metal specifications to optimize your stamping application.

We can stamp metal in any temper, in gauges from 0.010″ to 0.500″, That’s 2.5mm to 12.7mm for our metric friends. These are guidelines only, and depending on many variables we can go outside of this range.

To learn more about our progressive metal stamping capabilities, or to discuss your project with an applications engineer, Contact Talan Products today!

Global Customers for Our Stampings

Talan worldwide and U.S. customers rely on us for mid to high volume:

- Aluminum Stampings

- Automotive Stampings

- Metal Stampings

- Progressive Die Stampings

- Long Run, High Speed Stamping

- Stainless Steel Stampings

- Solar Energy Components

- EV stampings

- LED Lighting components

- Building Products stampings

Shipping custom quality progressive die stampings around the globe, Talan Products provides you world-class quality assurance and precision stamping technology. Stamping your parts from stainless steel, aluminum or other metals demands precision. Our ISO 9001 registered quality system assures you defect-free stamped metal parts with the tight tolerances you need at high volume production rates.

Whether you’re an engineer beginning a project and looking for high volume-high value progressive die stamping capabilities, or a purchasing professional seeking a quality-driven vendor for stamping metal, please let us quote your progressive die stampings.

More resources

Why is Metal Stamping so Cost-Effective? CLICK HERE

What are the best metals for metal stamping? CLICK HERE

Are you looking at onshoring? Reshoring? The best domestic metal stamping partner? CLICK HERE

How to choose the right metal stamping partner CLICK HERE

Facebook

Facebook Twitter

Twitter LinkedIn

LinkedIn YouTube

YouTube