Resources and White Papers

An Introduction to Metal Stamping

March 12th, 2025What is Metal Stamping?

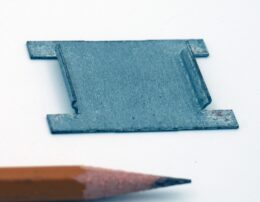

Example of a Simple Stamping

Metal stamping is a manufacturing process that transforms flat sheet steel—whether in coil or blank form—into precise, functional components. This is done using a machine and specialized tooling to alter the shape, add features, or refine the profile of a part. Metal stamping is highly versatile, allowing for the production of simple parts as well as intricate, complex components with multiple features.

(Graphic: Simple metal stamping parts) (Graphic: Complex metal stamping parts)

Metal Stamping Dies: The Tools Behind the Process

A die is a custom tool placed into a stamping press to perform the required operations. There are two main types of dies used in metal stamping: single-hit dies and progressive dies.

- Single-Hit Dies (Line Dies): In a single-hit die, the material is either manually or mechanically fed into thedie, and all operations are performed in one stroke of the press. This can be as straightforward as cutting out a shape (blanking). Sometimes, single-hit dies are part of a production line where parts move through multiple presses, each performing a different operation.

- Progressive Dies: With a progressive die, material—typically from a coil—is automatically fed through the die. At each press stroke, the material advances, and different operations occur at various stations within the die. This method allows for the efficient, high-speed production of complex parts while reducing labor and handling costs.

Example of a Complex Metal Part Stamping

(Graphic: Example of a “single-hit” part) (Graphic: A progressive die part – didn’t find)

Punch Press Machines: The Workhorses of Metal Stamping

Punch presses vary in size, construction, and force capacity (tonnage).

- Small presses, such as a 1-ton punch press, can sit on a bench and produce enough force to shape lightweight materials.

- Large presses, like a 600-ton press, require reinforced flooring and generate immense pressure to form heavy-gauge metals.

- High-speed progressive die presses can exceed 1,000strokes per minute, while massive presses can generate 2,000 tons or more of force to stamp large parts.

(Graphic: 5-ton single-hit punch press – didn’t find) (Graphic: 600-ton press for progressive dies)

Mass Production of Metal Parts

What qualifies as “mass production” varies by industry. For some, 500 parts per year is a high volume, while others manufacture over 100 million pieces annually. Regardless of volume, metal stamping is

ideal for mass production due to its efficiency and repeatability.

Example of a Single Hit Part

The estimated annual quantity (EAQ) helps determine the best tooling solution. At Talan Products, we assist customers in selecting the optimal tooling strategy to ensure the lowest possible piece price and total project cost over the product’s lifespan.

Common Metal Stamping Operations

Metal stamping encompasses a variety of forming and cutting techniques, including:

- Bending: Forming metal along a straight or curved line.

- Blanking: Cutting a part completely from a metal sheet.

- Coining: Compressing a design into metal (similar to coin faces).

- Curling: Creating a tubular shape (e.g., hinges).

- Cutting: Separating material from the coil or sheet.

- Drawing: Stretching metal to form deep shapes (e.g., oil filters).

600 Ton Press

- Embossing: Pressing shallow designs into metal (e.g., lettering or logos).

- Flanging: Creating a raised ridge or edge.

- Hemming: Folding an edge over itself for reinforcement.

- Ironing: Compressing metal to a uniform thickness (e.g., soda cans).

- Piercing: Punching holes in metal (e.g., washers).

- Reducing/Necking: Decreasing a part’s diameter.

- Stretching: Thinning and shaping metal over a die (e.g., car doors).

Industries That Rely on Metal Stamping

Metal stamping is a $215 billion global industry (2024) and continues to grow at over 4% annually. Nearly every sector incorporates stamped metal components due to their strength, durability, and cost-effectiveness. Some industries that depend on metal stamping include:

- Aerospace

- Agriculture

- Ammunitions

- Appliances (Large & Small)

- Automotive

- Battery Storage

- Building Materials

- Construction

- Consumer Goods

- Electronics

- Firearms & Security

- Furniture

- HVAC Systems

- Jewelry

- Lawn & Garden Equipment

- Lighting

- Locks & Security Hardware

- Marine & Boating

- Medical Devices

- Plumbing

- Power Tools

- Solar Energy

- Telecommunications

- Toys

Why Choose Metal Stamping?

Metal stamping is a highly efficient, scalable, and cost-effective manufacturing process. Whether producing a few thousand or millions of parts, our expertise in progressive die stamping, precision tooling, and mass production ensures superior quality, efficiency, and cost savings.

Looking for a reliable metal stamping partner? Contact us today to discuss your project needs!

Copyright 2025 Woodie Anderson / Talan Products

Posted in: Resources and White Papers

Facebook

Facebook Twitter

Twitter LinkedIn

LinkedIn YouTube

YouTube