Resources and White Papers

Why is Metal Stamping So Cost-Effective?

March 12th, 2025Answer: Metal stamping is one of the most efficient and cost-effective manufacturing processes, especially for high-volume production. The key advantage? With every stroke of the press, a finished part is produced. That could mean one part every few seconds or more than 500 parts per minute—significantly reducing labor and production time.

Why Does Metal Stamping Save So Much Money?

If a part can be made from sheet steel with a uniform thickness (except in areas intentionally formed or thinned), it is likely an excellent candidate for metal stamping.

For small production runs, fabrication methods such as laser cutting, water jetting, plasma cutting, or shearing can be used. Holes can be punched faster than drilled, and forming can be done with standard brake press tooling. If your volume is low, these methods may make sense since they require little to no tooling investment. However, machine time and labor costs add up quickly.

A Real-World Cost Comparison: Fabrication vs. Progressive Die Stamping

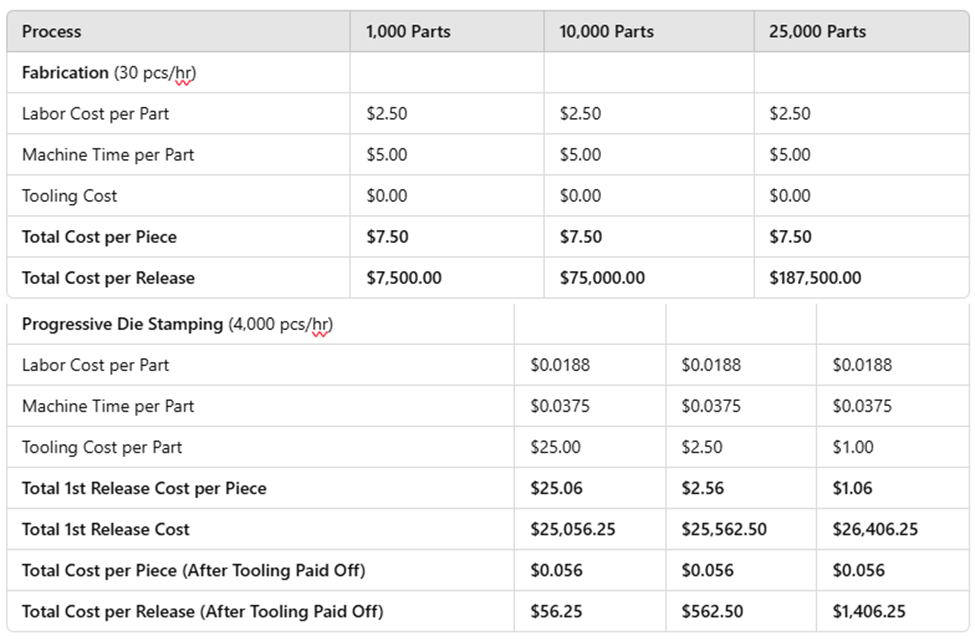

Let’s say we need to manufacture a widget—a stamped metal part with a few holes and a formed edge. Nothing too complicated. If we opt for fabrication, we avoid tooling costs, but production speed is slow. If we invest in a progressive die, we can stamp the same part much faster and at a lower cost per piece over time.

Cost Comparison Matrix

Here’s a breakdown of how production costs compare between fabrication and progressive die stamping, using a hypothetical $25,000 die investment:

What Do These Numbers Mean?

In this case, the investment in a progressive die pays off quickly. The first release of parts has the tooling cost included, making an apples-to-apples comparison against fabrication. However, once the die is paid off, the cost per part drops dramatically, making high-volume production significantly more affordable.

Of course, these are simplified numbers. Depending on the complexity and size of the part, progressive dies can range from $10,000 to $300,000, and production rates can exceed 500 parts per minute. Every project has unique parameters, but in most cases, metal stamping delivers unbeatable efficiency and cost savings.

Want to See How Much You Could Save?

Would you like to use your numbers? Contact us today with your widget—or any stamped metal part—and through our Early Supplier Involvement (ESI) program, we’ll help you “run the numbers” and determine the most cost-effective manufacturing method.

Better yet, if you involve us early in the design phase, our Design for Manufacturability (DFM) expertise can help reduce costs before tooling is even built.

? Learn More About Design for Manufacturability

? Contact Us Today to Optimize Your Stamped Metal Parts!

Mass Production of Metal Parts

Single Hit Press

Progressive Die Stamping

Copyright 2025 Woodie Anderson / Talan Products

Facebook

Facebook Twitter

Twitter LinkedIn

LinkedIn YouTube

YouTube